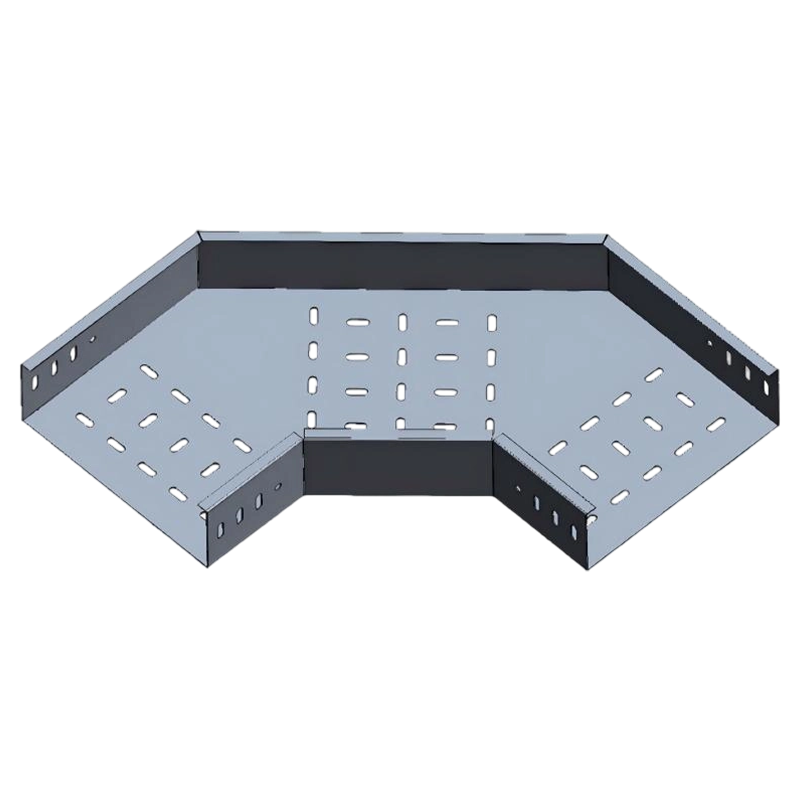

Perforated cable tray horizontal 90° elbow adopts a right-angle turning structure design, with an overall 90° turning state, which is suitable for scenarios where cables need to be turned horizontally. The bottom and sides continue the standard perforated structure, and the opening rate of the perforated structure is designed to be no less than 30%, which can effectively reduce the heat accumulation generated by the cable when it is working, further extend the service life of the cable and improve the operation stability. Compared with traditional closed cable trays, this product has better heat dissipation performance in high-density cable operation environments, and is especially suitable for high-heat load scenarios such as data centers, power control rooms, and large manufacturing workshops. The structural design of this elbow also takes special considerations on the control of the cable bending radius, and adopts a standard inner bend radius design to ensure that the cable will not be damaged or broken due to too small a bending angle during the turning process, and the cable can maintain a good curve transition when passing through the elbow component.

As a famous China Perforated cable tray horizontal 90° elbow Manufacturers and Perforated cable tray horizontal 90° elbow Factory. we are a professional factory that produces and sells various types of cable trays, solar brackets, marine trays, bus ducts and their accessories. The cable tray styles produced by our factory are divided into cable ladder, cable trunking, perforated, marine cable ladder, etc. The materials are divided into: steel , stainless steel 304/316, aluminum alloy , fiberglass , and fireproof cable tray . Surface treatment is divided into: cold galvanizing, hot-dip galvanizing, spray coating, etc. The design department can select the required product type and surface treatment based on on-site construction. The product is widely used in industries such as coal, chemical, metallurgical, steelmaking, power generation, pharmaceuticals, solar power generation, water treatment, wind power generation, and shipbuilding. We can provide users with complete cable laying, installation of supporting products and solutions. And our company is a first tier agent for lightweight solar panels.

We are high-quality suppliers to major companies such as State Grid Heilongjiang Electric Power Co., Ltd., Zoomlion Heavy Industry Science and Technology Co., Ltd., and Jinchuang Group Co., Ltd; The products are exported to various parts of the country such as Xinjiang, Ningxia, Guangxi, etc. Our clients are located in over 100 countries and regions around the world, including Singapore, the Philippines, Thailand, South Korea, Kenya, and South America. We welcome you to visit and inspect our company on site. Looking forward to becoming your partner.

-

1. Why Proper Cable Ladder Rack Installation is Critical for System Safety? In industrial facilities and data center infrastructure, a Cable Ladder Ra...

READ MORE -

In industrial infrastructure, the management of cables is as critical as the machinery they power. For decades, galvanized and stainless steel were th...

READ MORE -

On January 13, 2026, Mac, the founder of JIANGSU ZEXIN ELECTRIC TECHNOLOGY CO.,LTD., and his wife Judy visited the Singapore branch to plan for overse...

READ MORE -

In the intricate world of industrial electrical engineering, the perforated cable tray is far more than a simple metal bracket; it is a critical compo...

READ MORE -

Shipboard electrical systems are some of the most complex and critical infrastructures on any vessel. With engines, navigation systems, communication ...

READ MORE

English

English عربى

عربى Français

Français Español

Español Português

Português