Advantages of Using Wire Mesh Cable Trays

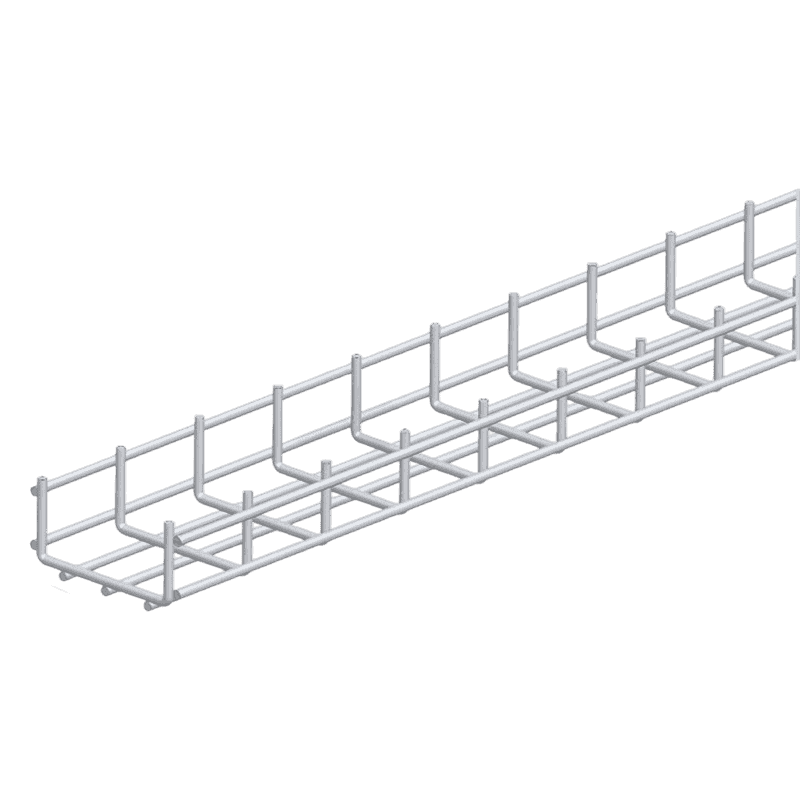

Wire mesh cable trays are a more affordable option when compared to other cable management systems. Their lightweight construction, ease of handling, and simple design reduce the overall cost of materials, transportation, and installation. At Jiangsu Zexin Electric Technology Co., Ltd., we focus on providing a product that offers both affordability and quality. The minimal material used in the construction of wire mesh trays results in lower production costs, which translates to savings for our clients. The ease of installation is a major cost-saving factor. Traditional cable trays or conduits often require extensive labor, specialized tools, and more time to install, which can increase both direct and indirect costs. In contrast, wire mesh trays are quicker to install due to their modular nature and simple design. Our products are designed for straightforward installation, reducing the need for additional labor or complex equipment. The reduced installation time leads to faster project completions and lower overall costs, particularly in large-scale industrial projects. Wire mesh trays require less ongoing maintenance. Their open structure allows easy access for inspection and repairs, so maintenance costs are minimized over time. With Jiangsu Zexin Electric Technology Co., Ltd.’s durable and corrosion-resistant trays, users can expect reduced replacement and repair needs, contributing to long-term cost savings.

The significant advantage of wire mesh cable trays is their ability to provide superior ventilation for cables. The open-grid design of the wire mesh allows for airflow around the cables, which helps prevent overheating—a common issue in cable management systems. In environments where cables are exposed to constant current or high-voltage operations, maintaining a safe temperature is critical. Wire mesh trays prevent heat buildup, keeping the cables cool and reducing the risk of electrical failures or fire hazards. At Jiangsu Zexin Electric Technology Co., Ltd., we design our wire mesh cable trays with this very principle in mind. Our products promote optimal airflow around the cables, ensuring that even high-density installations can maintain their efficiency and safety. This ventilation not only prevents overheating but also ensures that moisture does not accumulate within the system, which could lead to rust or corrosion over time. The enhanced ventilation offered by our trays helps improve the overall longevity of the cable system. With better cooling, cables will maintain their integrity and performance longer, minimizing the need for frequent replacements. This is particularly beneficial in industries such as power generation, telecommunications, and industrial manufacturing, where large volumes of cables are used, and continuous operation is critical.

Wire mesh cable trays are known for their ease of installation, which is a key factor in reducing project timelines and costs. The installation process for wire mesh trays is typically faster than other types of cable management systems. Their modular design allows for flexibility during installation, enabling quick adjustments to fit specific project requirements. The trays can be easily mounted on walls, ceilings, or suspended from overhead structures, depending on the needs of the installation. At Jiangsu Zexin Electric Technology Co., Ltd., we ensure that our wire mesh trays are designed for effortless installation, requiring fewer tools and less labor. Unlike traditional solid trays, which often require more precise measurements and customization, wire mesh trays are easier to handle and cut, making the installation process quicker. This simplicity reduces the chance for errors and adjustments during installation, further speeding up project timelines. The modular nature of our wire mesh trays allows for easy reconfiguration if adjustments need to be made during or after installation. This flexibility ensures that the cable management system can evolve along with the changing needs of the project. Whether cables need to be added, removed, or rearranged, our trays can accommodate these changes without requiring significant work or additional resources.

Wire mesh cable trays are built to be strong and durable, able to support heavy cables in both indoor and outdoor environments. The materials used in manufacturing these trays, such as stainless steel, galvanized steel, aluminum, and fiberglass, offer high levels of strength, ensuring that they can support large quantities of cables without bending, warping, or breaking. This is especially critical in industries like steel manufacturing, power generation, and shipbuilding, where the weight and volume of cables are substantial. At Jiangsu Zexin Electric Technology Co., Ltd., we ensure that our wire mesh trays meet the highest standards for strength and durability. Our trays are designed to withstand both physical stresses and environmental challenges. For example, stainless steel trays provide superior strength and are resistant to corrosion, making them ideal for use in harsh environments such as chemical plants or offshore installations. For lighter, more flexible installations, we offer aluminum alloy trays, which combine strength with lightweight properties. The durability of our trays also means they have a longer lifespan, reducing the need for frequent replacements or repairs. This makes them a wise long-term investment for any company, as the cost of ownership is minimized due to fewer maintenance requirements.

The flexibility of wire mesh cable trays is one of their greatest strengths. The modular design of the trays allows for easy modifications to fit changing requirements. Whether cables need to be rerouted or expanded, wire mesh trays can be adjusted quickly and efficiently. This makes them ideal for projects that may evolve over time or where future expansions are anticipated. At Jiangsu Zexin Electric Technology Co., Ltd., we ensure that our wire mesh trays are adaptable to a wide range of project types, from small office buildings to large industrial plants. The trays can be configured in a variety of ways to accommodate different types of cables and complex routing systems. Whether you're working with power cables, fiber optic cables, or control wiring, our trays can be customized to suit specific needs. The flexibility of wire mesh trays also extends to their installation. Unlike rigid cable trays that require precise measurements and custom modifications, our trays can be easily altered during installation. They can be cut, bent, or extended to fit specific requirements, which reduces the likelihood of delays or complications.

The open design of wire mesh cable trays helps to significantly reduce the risk of fire hazards compared to traditional cable management systems. By allowing air to circulate freely around the cables, wire mesh trays prevent the buildup of heat that could lead to overheating and fire. The materials used to manufacture wire mesh trays, such as stainless steel and fire-resistant fiberglass, offer additional protection against fire. At Jiangsu Zexin Electric Technology Co., Ltd., we place great emphasis on fire safety in the design and manufacture of our wire mesh cable trays. Our fire-resistant options, combined with the trays' open structure, help mitigate the risks associated with electrical fires. These trays can be used in a variety of environments where fire safety is a priority, such as in chemical plants, power stations, and data centers. By investing in fire-resistant wire mesh trays, companies can ensure a safer working environment and reduce the risk of damage to critical infrastructure. The ease of maintaining these trays also plays a role in fire prevention, as they can be inspected regularly for wear and damage, ensuring early detection of potential issues.

Wire mesh cable trays are ideal for use in corrosive environments, thanks to their ability to resist rust and degradation. Materials such as stainless steel, galvanized steel, and aluminum offer excellent resistance to corrosion, ensuring that the trays maintain their structural integrity even when exposed to moisture, chemicals, or extreme weather conditions. This is particularly important in industries like shipbuilding, oil and gas, and chemical processing, where exposure to corrosive substances is inevitable. At Jiangsu Zexin Electric Technology Co., Ltd., we offer a variety of materials that are specifically designed to withstand corrosive environments. Stainless steel trays, for example, are highly resistant to corrosion and are ideal for marine environments or installations near saltwater. Similarly, our fiberglass trays offer excellent resistance to chemical corrosion, making them suitable for use in industries where chemicals are handled regularly. The corrosion resistance of our trays ensures that they will continue to perform effectively even in the harshest environments. This not only improves the safety and reliability of the cable management system but also reduces the long-term costs associated with repairs and replacements.

English

English عربى

عربى Français

Français Español

Español Português

Português