Benefits of Using Cable Trunking Systems in Industrial Installations

Industrial environments often subject cables to a variety of hazards such as mechanical impact, chemical exposure, high temperatures, moisture, and electrical interference. If cables are left exposed or poorly managed, the risk of damage is significantly higher.

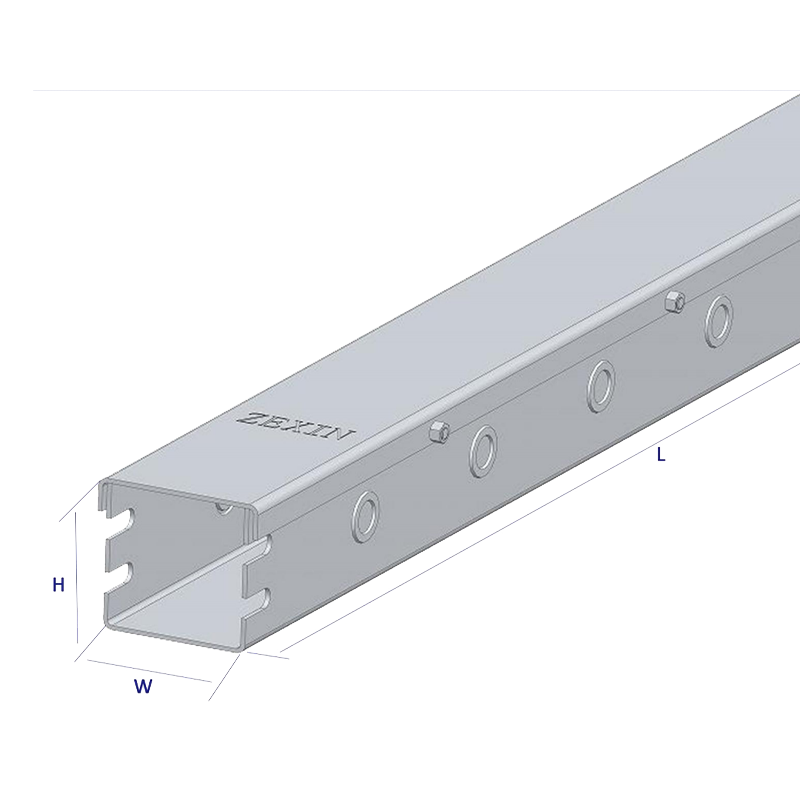

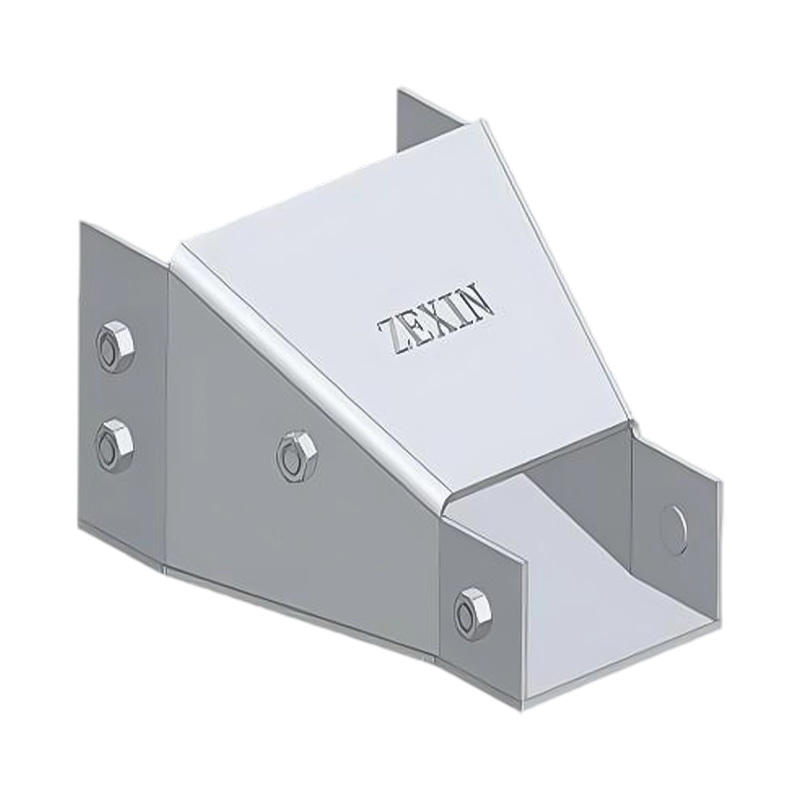

Cable trunking systems offer a robust solution by enclosing cables in protective housings that guard them against physical wear and environmental stress. The materials used for cable trunking systems are carefully chosen to enhance the durability and longevity of the cables inside. For example, our trunking systems made from stainless steel or aluminum alloy are resistant to corrosion, making them ideal for use in coastal or chemical plants where cables may be exposed to moisture and corrosive substances. Materials like fiberglass or fire-resistant coatings protect cables from high temperatures and flame exposure, which are common risks in power generation, chemical processing, and steel manufacturing. The system’s protective features also reduce the likelihood of electrical hazards. Cables housed within trunking systems are less prone to short circuits caused by physical damage. With well-organized cable pathways, the risk of cables rubbing against sharp edges or being crushed is minimized. The trunking enclosures prevent accidental exposure to live cables, which could pose serious safety risks to workers. At Jiangsu Zexin Electric Technology Co., Ltd., we ensure that our cable trunking systems are designed to provide comprehensive protection against a wide range of environmental factors, ensuring that cables are secure, operational, and long-lasting.

Electrical safety is a top priority in industrial installations. Exposed or poorly managed cables can lead to numerous hazards, including electrical shocks, short circuits, fires, and even explosions. A poorly managed cable network can present not only physical risks to workers but also increase the likelihood of operational downtime due to electrical faults. Cable trunking systems mitigate these risks by effectively containing and organizing cables. By housing cables in secure trunking systems, we reduce the likelihood of accidental damage to cables, which could result in sparks, overheating, or electrical fires. Our cable trunking products, made from materials with high electrical insulation properties, ensure that cables are adequately protected from accidental exposure to conductive elements. For example, Jiangsu Zexin Electric Technology Co., Ltd. produces fiberglass and steel cable trunking systems that help reduce the risk of electric shock by isolating cables from external elements. These materials also provide an added layer of fire resistance. With a properly installed trunking system, cables are not left dangling or exposed, which prevents unintentional contact with personnel or equipment. Cable trunking systems make it easier to maintain an organized network of cables, reducing the chances of miswiring or creating pathways that are prone to overloading. This reduces the risk of overheating, which can lead to fires or electrical failures. The use of cable trunking systems, therefore, contributes significantly to improving the overall safety of industrial facilities, ensuring the protection of both employees and assets.

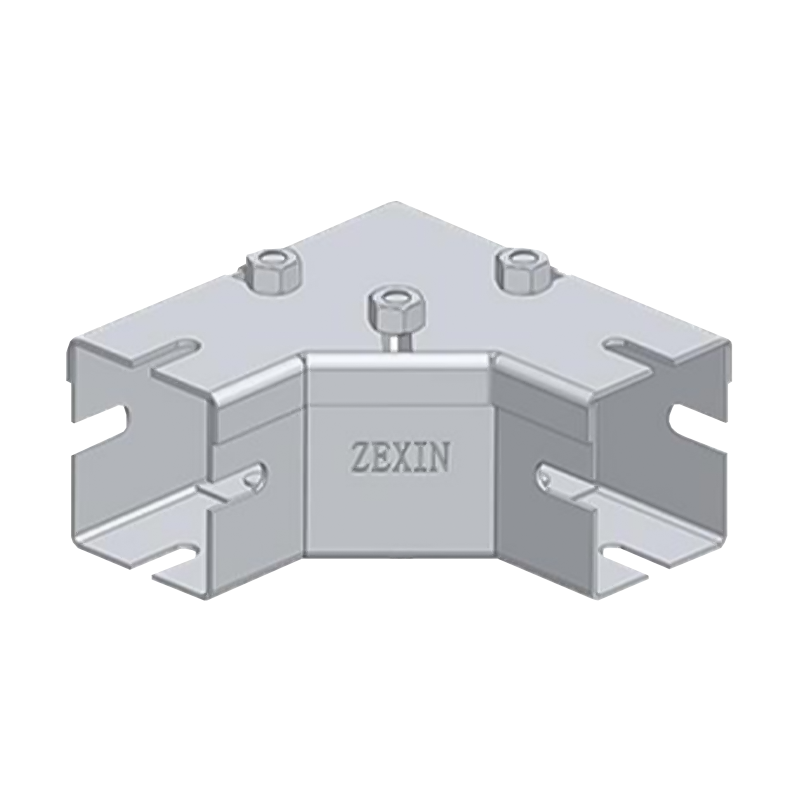

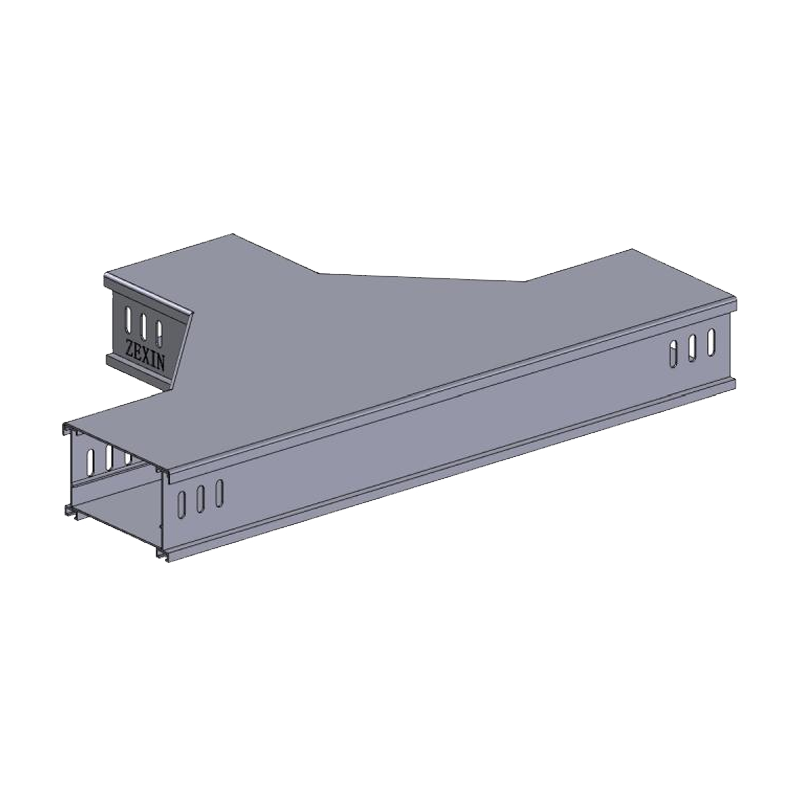

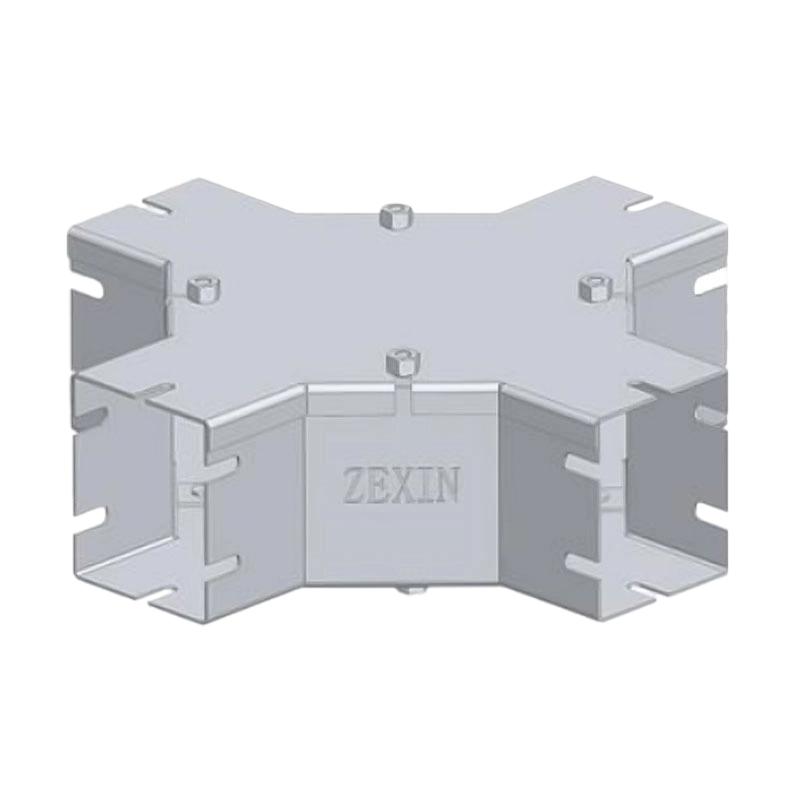

Maintaining and servicing cables in an industrial setting can be a challenging task if cables are not properly organized. Over time, cables may need to be replaced, rerouted, or tested for integrity, especially in complex electrical networks. Without an organized cable management system, accessing specific cables for maintenance or troubleshooting can become a time-consuming and error-prone process. Cable trunking systems simplify this task by keeping cables organized, labeled, and easily accessible. With our systems, cables are laid out in designated pathways that allow for clear visibility and easy identification. This makes it simpler for maintenance personnel to locate specific cables when needed, reducing time spent on maintenance and minimizing downtime during repairs or upgrades. The trunking system also allows for future modifications and additions. As industrial facilities expand or new equipment is introduced, additional cables may need to be routed through the system. Jiangsu Zexin Electric Technology Co., Ltd.’s trunking systems are flexible and can be adapted to accommodate additional cables without requiring major alterations to the existing installation. This feature not only simplifies maintenance but also helps reduce the costs associated with expanding electrical infrastructure. By housing cables in a clear, organized manner, the trunking system also minimizes the risk of damage during routine maintenance activities. Cables are kept securely in place, which makes it less likely that they will be accidentally disturbed or disconnected during repairs. This ease of access improves the overall operational efficiency of industrial facilities and ensures that any necessary maintenance tasks are completed quickly and safely.

Space is often a limited and valuable resource in industrial installations. In factories and power plants, there is a constant need to optimize available space for operational efficiency. Poor cable management can result in cables being scattered across the floor or tangled in a way that obstructs movement or interferes with equipment. Cable trunking systems provide an organized and compact solution that maximizes available space. By housing multiple cables within a single trunking system, Jiangsu Zexin Electric Technology Co., Ltd.’s solutions help to minimize the amount of floor space dedicated to cable networks, freeing up more room for equipment or production areas. Trunking systems can be mounted on walls, ceilings, or under floors, depending on the space configuration, to keep cables neatly contained and out of the way of other activities. The compact design of cable trunking systems also improves airflow around cables. In some industrial settings, such as data centers or power generation plants, overheating can pose a serious risk to electrical components. By ensuring that cables are housed in a structured, ventilated environment, trunking systems help maintain proper airflow, reducing the likelihood of overheating and cable failure. At Jiangsu Zexin Electric Technology Co., Ltd., we offer a range of trunking system designs, including cable ladders and perforated trays, which help optimize the use of space while providing the necessary protection and support for cables. This space-saving feature is especially valuable in large industrial plants, where maximizing the use of floor space is essential for maintaining smooth operations.

While aesthetics may not be the highest priority in all industrial settings, the visual appeal of an installation can have an impact on the overall perception of a facility. In industries where appearances matter—such as pharmaceuticals, food processing, or facilities that host clients for tours—maintaining a neat and organized workspace is crucial. Cable trunking systems offer a clean, streamlined solution that helps improve the aesthetic appeal of industrial spaces. With cables contained within protective trunking, there is no clutter of exposed wires or cables running along the floor or ceiling, which can create a chaotic and unprofessional appearance. This contributes to a cleaner and more organized working environment, making the space safer and more visually appealing to visitors and employees alike. At Jiangsu Zexin Electric Technology Co., Ltd., our cable trunking products come in various styles and finishes that can blend seamlessly into a wide range of industrial settings. Whether our clients are seeking a functional solution for cable management or a system that also meets aesthetic requirements, we provide options that suit their needs. The sleek, modern design of our trunking systems helps elevate the professional look of any industrial facility. By keeping cables organized and neatly contained, cable trunking systems can also improve overall workplace morale. A clean, well-maintained environment contributes to a more efficient and positive work atmosphere, reducing the chances of accidents and enhancing the overall experience for employees and visitors.

In industrial settings, it is essential to invest in systems that will withstand the test of time. Cable trunking systems must be durable enough to handle the physical and environmental stresses placed upon them. High-quality materials and manufacturing standards ensure that cable trunking systems can endure without the need for frequent replacements or repairs. Jiangsu Zexin Electric Technology Co., Ltd. manufactures cable trunking systems from materials like stainless steel, aluminum, fiberglass, and fire-resistant coatings. These materials provide excellent resistance to corrosion, high temperatures, and physical wear, ensuring the longevity of the system even in harsh industrial environments. Stainless steel trunking systems, for example, are ideal for marine environments where corrosion from saltwater is a concern. Similarly, fiberglass trunking systems are perfect for high-temperature environments where fire resistance is required. Investing in durable cable trunking systems may have a higher upfront cost, but the long-term benefits make it a cost-effective choice. The durability of these systems reduces the frequency of repairs or replacements, saving money on maintenance in the long run. The improved efficiency and safety provided by a well-organized cable management system can lead to reduced operational downtime, further contributing to cost savings. In the long run, the reliable performance of cable trunking systems from Jiangsu Zexin Electric Technology Co., Ltd. can help industrial clients avoid the hidden costs associated with poorly managed cable installations. With a robust, long-lasting cable management solution, our clients benefit from reduced operational disruptions, lower maintenance costs, and improved overall system performance.

English

English عربى

عربى Français

Français Español

Español Português

Português