Cable tray straight adopts a coverless U-shaped straight section design, and the overall structure is simple and practical. Its core structure is a U-shaped trough, and the edges on both sides are des...

READ MOREWhat Is the Difference Between Perforated and Solid Bottom Cable Trays?

Introduction

In modern electrical and industrial installations, cable management is crucial for safety, efficiency, and longevity. Cable trays are widely used to organize, support, and protect electrical cables. Among these, perforated cable trays and solid bottom cable trays are two popular types. Understanding their differences is essential for choosing the right tray for your specific project.

1. What Is a Perforated Cable Tray?

A perforated cable tray is characterized by a series of holes or slots along its base and sometimes on the sides. These perforations serve multiple purposes:

- Ventilation and Heat Dissipation: The holes allow air to circulate freely around the cables, preventing overheating, which is particularly important for high-current power cables or densely packed data cables.

- Moisture and Dust Control: Perforations allow any water, dust, or debris to pass through the tray, reducing corrosion risk and easing maintenance.

- Weight Reduction: The cutouts reduce the overall weight of the tray, making installation easier and less labor-intensive.

- Flexibility in Cable Management: Slots provide convenient points for securing cables with ties or clamps.

Common materials used:

- Galvanized steel (GI) – offers moderate corrosion resistance

- Stainless steel – ideal for corrosive environments

- Aluminum – lightweight and rust-resistant

- Powder-coated steel – for aesthetic and protective purposes

Best applications:

- Indoor industrial environments

- Data centers and telecommunication rooms

- Control panels and low-to-medium load electrical installations

2. What Is a Solid Bottom Cable Tray?

A solid bottom cable tray is a fully enclosed tray without any perforations. Its design provides maximum protection for the cables:

- Protection from External Elements: Dust, moisture, chemicals, and mechanical impact are prevented from reaching the cables.

- Enhanced EMI/RFI Shielding: Sensitive communication and control cables are less susceptible to electromagnetic interference.

- Load Support: Solid trays can sometimes support heavier cables since the base is continuous.

- Clean Appearance: A solid base provides a sleek and uniform look, often preferred in visible installations.

Common materials used:

- Mild steel – for heavy-duty applications

- Stainless steel – for corrosive environments

- Aluminum – for lightweight, durable installations

Best applications:

- Outdoor industrial sites

- Environments with high dust, moisture, or chemical exposure

- Projects requiring heavy-duty cable protection

3. Key Differences Between Perforated and Solid Bottom Cable Trays

Below is a detailed comparison to help you quickly understand the differences:

| Feature | Perforated Cable Tray | Solid Bottom Cable Tray |

|---|---|---|

| Base Design | Multiple holes or slots | Fully enclosed, no holes |

| Ventilation | Excellent airflow | Limited airflow |

| Cable Protection | Moderate | High (dust, moisture, mechanical) |

| Weight | Lighter | Heavier |

| Heat Dissipation | High | Lower, may need external ventilation |

| Maintenance | Easy to access and tie cables | Harder to access; may require tray lifting |

| Cost | Lower | Higher due to more material used |

| Applications | Indoor, IT, control panels | Outdoor, heavy-duty, dusty, or corrosive environments |

This table illustrates the trade-offs between the two types of trays, making it easier to choose the right option for your project.

4. How to Choose Between Them

Choosing between perforated and solid bottom cable trays requires careful consideration of several factors:

-

Environment:

- Indoor vs. outdoor, dry vs. humid, clean vs. dusty.

-

Cable Type and Heat Requirements:

- Power cables generating heat may benefit from perforated trays for airflow.

- Sensitive communication cables may need solid trays for EMI shielding.

-

Load Capacity:

- Consider the total weight of cables and whether the tray needs to support heavier industrial cables.

-

Maintenance and Future Expansion:

- Perforated trays are easier for frequent cable addition or removal.

-

Budget:

- Perforated trays generally cost less, but solid trays offer greater protection at a higher price.

Quick Tip:

- If ventilation and cost efficiency are your priorities → choose perforated cable trays.

- If maximum protection and durability are your priorities → choose solid bottom cable trays.

-

-

According to different wiring requirements, the perforated cable tray reducer is divided into two structural forms: concentric reducer and eccentric reducer. Concentric reducer means that the width of...

READ MORE -

The core design of the cable ladder reducer is a trapezoidal gradual transition structure. The structure adopts a ladder-type bridge beam body, and the bottom is supported by a crossbar to ensure the ...

READ MORE -

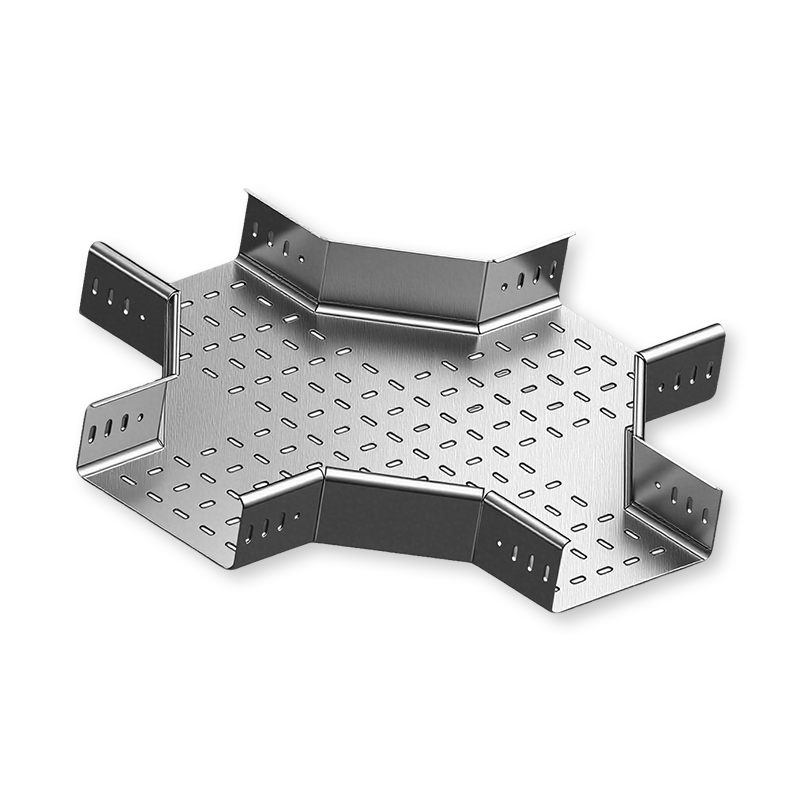

Cable ladder cross adopts a cross-reinforced structural design. This structure achieves uniform distribution of bridge force through precise alignment of the four-way crossbars. Each crossbar is on th...

READ MORE

-

1.Choosing the Right Cable Trunking Type Cable trunking systems are solutions used to protect cables and ensure their sa...

READ MORE -

Introduction to Wire Mesh Cable Trays What are Wire Mesh Cable Trays? A wire mesh cable tray, also called a wire cable t...

READ MORE -

The Role of Perforated Cable Tray in Solar Power System Wiring Understanding Perforated Cable Trays and Their Functional...

READ MORE -

Cable Trunking: A Key Component in Reducing Electrical Hazards Electrical installations are an essential part of any mod...

READ MORE

English

English عربى

عربى Français

Français Español

Español Português

Português